- FISCHER Now Five models within the New Digital DMP series with Probes, Case or Stand.

- FISCHER DMP Handheld Instrument Software freely downloadable.

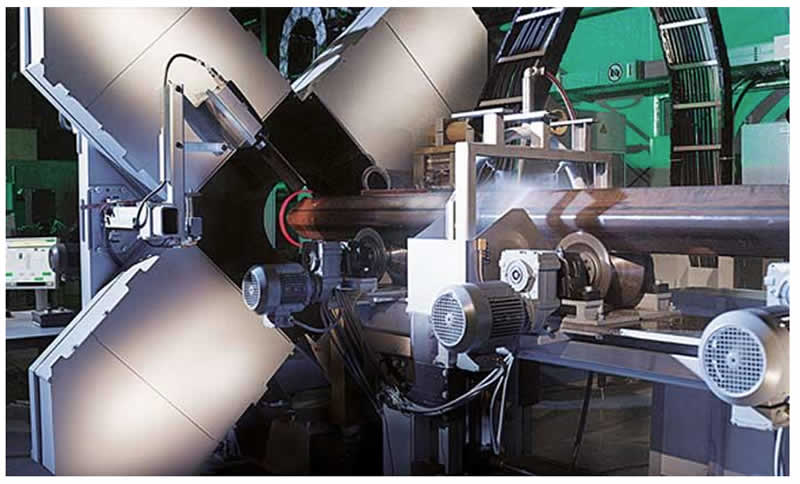

- FOERSTER DEFECTOVISION-IR high-performance heat flux thermography test system.

- DELTASCOPE® DMP®30 is the Magnetic inductive measuring Coating Thickness Instrument method. Measurement of non magnetic coatings on magnetic base materials

ISO on FE: Paint, lacquer, plastic coatings on Fe, steel

NF on FE: Zn, Cr, Cu on Fe, steel - DUALSCOPE® DMP®30 is the amplitude-sensitive eddy current method & magnetic inductive Coating Thickness Instrument measuring method. Measurement of non-magnetic or electrically non-conductive coatings on magnetic or non-magnetic, electricallyconductive base materials

ISO on NF: Paint, lacquer or plastic coatings on Al, Cu, CuZn

ISO on NF: Anodized layers on Al

ISO on FE: Paint, lacquer, plastic coatings on Fe, steel

NFE on FE: Zn, Cr, Cu on Fe, steel - FERITSCOPE® DMP®30 is the specialist instrument for measuring the Ferrite & Martensite Content in chemical plants, energy plants or process plants, engineering & fabrication, offshore plants, even in hard-to-reach places with the Industry Standard probe. Accurate FE & FN readings.

Determining the delta ferrite content in austenitic and duplex steels

Determining the proportion of deformation martensite in austenitic materials

Detecting weld seams in polished surfaces

Determining the ferrite content distribution along a weld seam - ISOSCOPE® DMP®30 is the amplitude-sensitive eddy current Coating Thickness Instrument method. Measurement of

electrically insulating coatings on non-magnetic, electrically conductive metals

ISO on NF: Paint, lacquer or plastic coatings on Al, Cu, CuZn

ISO on NF: Anodized layers on Al - SR-SCOPE® DMP®30 is the specialist instrument for measuring Copper Layers on PCBs. Check the copper thickness precisely and reliably without the influence of underlying layers in your production process, in incoming or outgoing goods.

Copper layer thicknesses from 0.5 – 10 µm and 5 – 120 µm

- NEW Protective Cover for the DMP Series of handheld instruments

- FREE PC Software for DMP Series handheld instruments, downloadable via a link

Innovative testing with FOERSTER

The benefits

- Fully automated testing unit with high repeatability helps Increases productivity

- Contactless method eliminating wear and tear, equals lower maintenance costs and significant time savings.

- Rigorous examination of steel billets, Cracks reliably detected even in critical edge areas.

- Inspection of the entire surface at of up to 1.5 m/s.

- Detection of the smallest defects at just 10 mm long and 0.3 mm deep.

- Less scrap due to tiny uninspected ends of just 5 mm.

- Modern testing methods for your quality assurance with high-performance heat flux thermography.

The DEFECTOVISION IR system is an addition to FOERSTER’s core competence, the non destructive testing of semi-finished metal products. All around the world, more than 6.5 million tons of steel have been tested safely and efficiently by now with our latest technology.

The automatic infrared technology applied by FOERSTER provides new approaches for previously impossible testing tasks.

Inductive heat flux thermography facilitates the testing of entire surfaces of hot-rolled steel billets and tubes with round, square, or rectangular cross-sections as well as rails and profiles. Flat surfaces as well as exterior and interior radiuses are tested fully and reproducibly. All but a few millimetres of the ends of the materials are also covered by the surface test.