- R. B. ANNIS – Magnetometer Calibration Checking Fixture

- NEW: TERASCOPE – Automated TERAHERTZ Non-Contact thickness measurement

- 3. APPLIED TEST SYSTEMS USA – Announce: Bending Beam Rheometer 2S UPGRADE

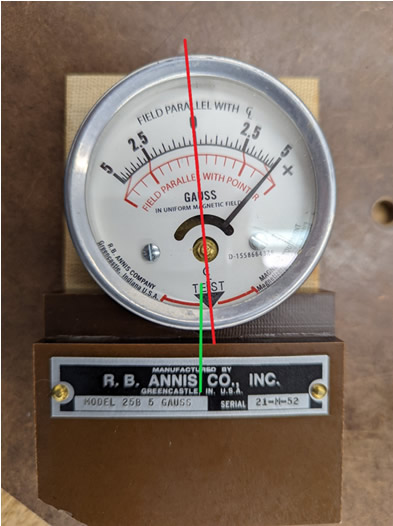

Model 25B V Block Style Calibration Checking Fixtures

25B checking fixtures are used to determine calibration accuracy of a Model 25 Gauss Pocket Magnetometers in any one range of 2, 5, 10, 20 Gauss. (50 Gauss also available at additional cost)

The Model 25B fixture was designed to be easier to use, eliminating the need for very accurate alignment of the tip of the scale test arrow with the index line on the name plate of the fixture.

Example:

- Ensure the full-scale gauss figure on the instrument dial and the gauss figure stamped on the fixture name plate are the same value.

HELMUT FISCHER

Unbeatable in automated TERAHERTZ measurement

Automated measurement solutions for non-destructive and contactless coating thickness measurement of organic single and multilayer coatings with THz

Advantages

- Market-leading measurement performance: Unsurpassed 6 THz bandwidth for highest precision and repeatability

- Patented Clean-Trace Technology: Dry air flushing for best measurement performance and unaltered results

- Integrated 3D scanner: With positioning sensors also for round surfaces and complex component shapes

- Vibration compensation: Unique 1.6 KHz sampling rate intrinsically compensates for all unwanted vibrations

- Easy integration: Hardware and software designed for use on the robot as well as in control systems

- High reliability: Robust, low-maintenance and designed for uninterrupted 24/7 use

- Electro-optical measurement: No moving mechanical parts guarantee maximum

Features

- Spot size: 1 mm

- Bandwidth: Up to 6 THz

- Acquisition speed (THz-Tracerate): 1.6 KHz

- Measurement time: Few seconds

- Positioning time: < 1 – 3 s, an accuracy of < 0.05 µm

- Measuring range: 10 μm up to several millimetres

- Number of layers: Up to 7

- Measuring distance: 7 cm

- Accuracy: < 1 μm or 1 % of thickness, dep. on app.

- Repeatability: < 0.1 μm, depending on application

APPLIED TEST SYSTEMS USA announce the upgrade of the Bending Beam Rheometer 2S with new software release version (2.8.1) and a newly redesigned LVDT calibration disk and weight pan.

New Software Enhancements:

- New Algorithm for LVDT standardization which improves calibration curve “fit” for the LVDT used with the BBR2S.

- Easier to understand instructions for Standardizing and Verifying the BBR, based on feedback.

- Standardization self-check routine incorporated for Load and Deflection Standardizations. This will alert operator to potential sensor issues or operator error in performing the standardization that could corrupt the calibration information saved in the software.

- Addition of Tare button for load cell output and Zero button for LVDT output to the main menu screen. This allows operator to re-tare or zero readouts without the need to re- standardize.

- Improvements to BBR3 Temperature Standardization

Redesign of Calibration Disk & Weight Pan:

- Redesign allows for standardizing the LVDT sensor with less possible error, by minimizing variations in positioning the weight pan during standardization

- Improved repeatability of deflection measurements