In This Issue:

1. New – ECHOMETER 1076 TC: New Transducer 2. Special – 30% OFF HSW Bespoke German Borescopes 3. News – Fischerscope UMP150 / Fischerscope ST200 4. Application – Compliance of coating thickness inside tanks

ECHOMETER 1076 TC: New Transducer for Hot Surfaces

The transducer can be used with the ECHOMETER 1076

Furthermore, in regular delay line materials the

Like more Information – 02 8850 3755

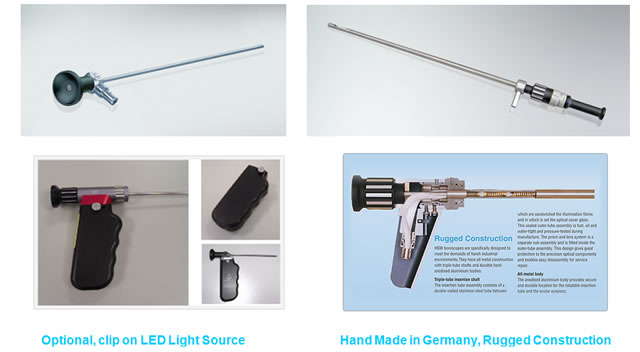

Whilst Stocks Last 30% of any Stock Henke Sass Wolf Borescope until March 2018 Like more Information – 02 8850 3755

FISCHERSCOPE® UMP 20, 40, 100 & 150.With their exchangeable probes, the ultrasonic gauges of the UMP series are ideal for measuring wall thickness Features • Dual-element probes for reliable results even on rough, corroded

• • Comes with probe DKS-537 (5 MHz UMP 20, 40, 100), DLK-1025 (10 MHz UMP 150); & many other probes also available, Application & High Temp. • Graphic display • Multi-language menu • Good life, 2 AA batteries • Robust, IP54-rated housing The FISCHERSCOPE® ST200 is Fischer’s first automatic scratch-test system for characterizing hard material layers. Easily check the adhesion and cohesive strength of layers ≥1 μm thick. The instrument is ideal for use in development, quality assurance, incoming goods control and production monitoring. Features Diverse measurement modes with progressive, constant or incrementally increasing test force. Measure according to the following norms: ASTM C1624, ISO 20502 & DIN EN 1071-3. Force control for measuring on curved surfaces. Three analysis methods: optical microscopy, friction force, acoustic emission. Intuitive user interface – only a brief familiarization is required to use the instrument. Fast measurements with motorized XY-stage and Z-axis. Easy creation of test reports Applications

Like more information– 02 8850 3755

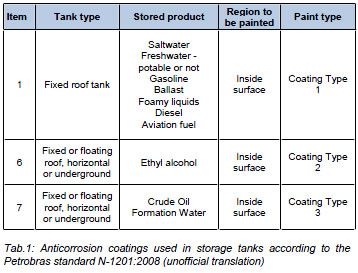

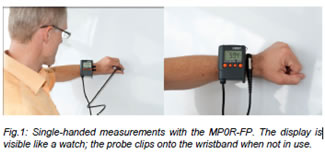

Complying with regulations concerning coating thickness inside storage tanks Anticorrosion coatings on the interior of storage tanks are critical when storing many types of products, Although there are many such regulations, the Petrobras standard, N-1201:2008 – “Anticorrosion Coatings for the A multinational company headquartered in Brazil, Petrobras uses the above-mentioned standard wherever it has The Petrobras standard N-1201:2008 prescribes the following coating types and coating thicknesses for the 4.2.1 Coating Type 1 4.2.1.1 Primer: one layer of epoxy-zinc phosphate paint: 100 μm 4.2.1.2 Top protective coating: two layers of non-solvent epoxy paint: 50μm minimum thickness per layer. 4.2.2 Coating Type 2: one layer of zinc-ethyl-silicate paint: 75 μm 4.2.3 Coating Type 3: one layer of non-solvent epoxy resin, cured with polyamine and embedded with ceramic or fibreglass: 800 μm Once they are applied, the coatings need to be inspected – a tricky job, because this is done in place! FISCHER developed the MP0x-FP products for just such applications performed under difficult conditions. While Another very practical advantage of the MP0R-FP series is that calibration can be done outside the tank using

Besides the unmatched accuracy & repeatability of the MP0R-FP series from FISCHER, extra N-1201:2008. For more information on the MP0R-FP series, please contact KK&S INSTRUMENTS Have any questions or like further details?; Ph 02 88503755 or Email

|