In This Issue:

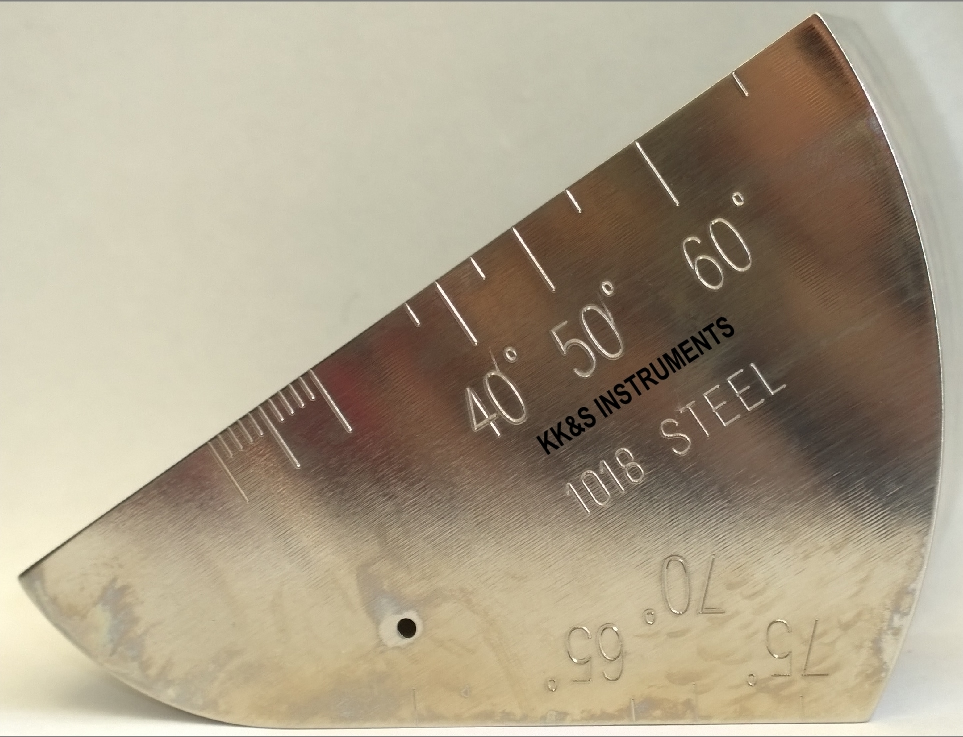

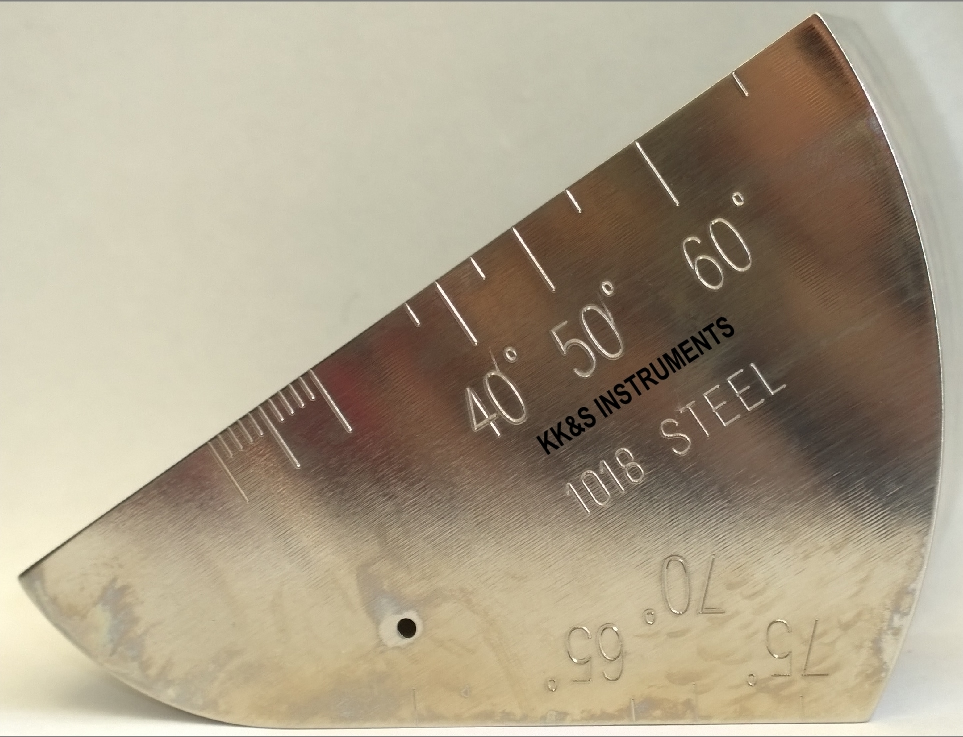

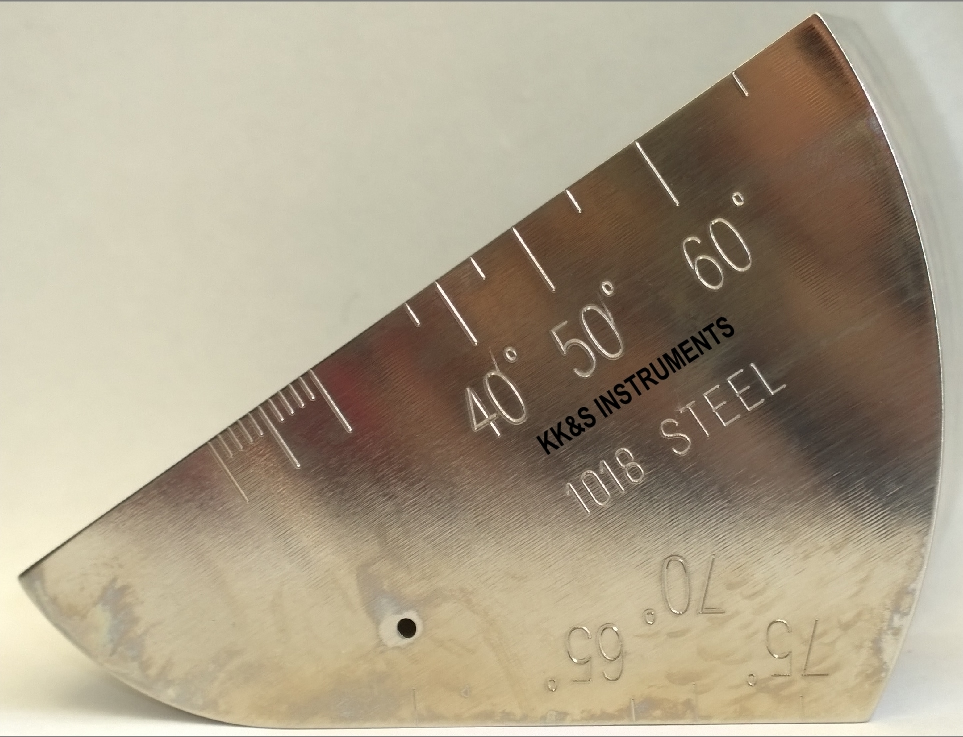

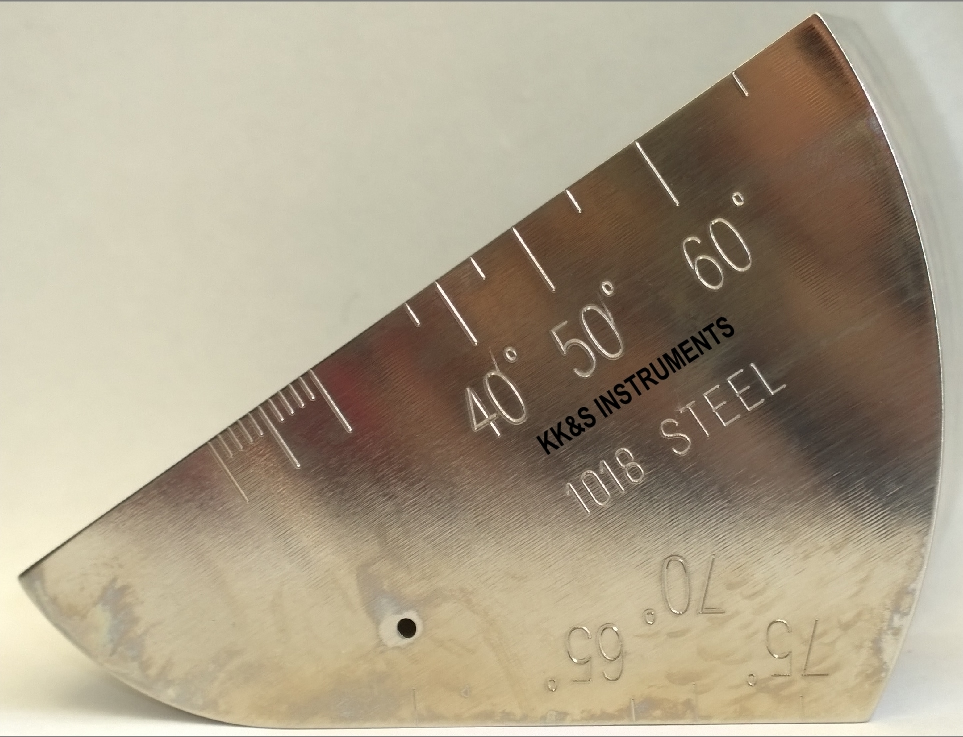

- Cover – Miniature Angle Beam Calibration Block

- News – From the Sales Desk – Applied Test Systems

= Pyro-Clean; Burn Off Residue from Lab Equip.

= PAV4: Asphalt / Bitumen Testing

- Special – 25% OFF – Miniature Angle Beam Blocks

- Application – Magnetic Phase Monitoring of STEEL

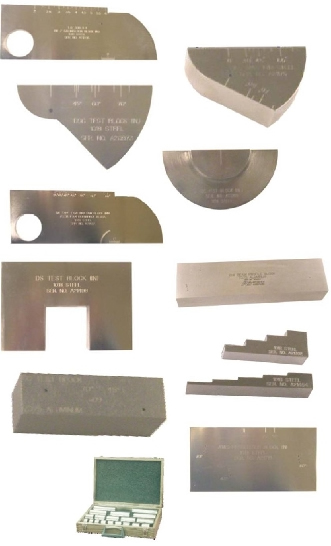

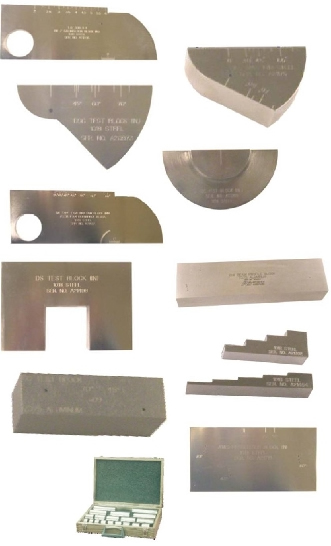

Manufactured in the United States Applied Test Systems offer an extensive line of ultrasonic calibration test blocks world renowned for quality and reliability.

ATS standard range is available in Imperial or Metric units, Steel, Stainless or Aluminium.

ATA offer Custom Units also available with; diameters, lengths, standard specifications, and other materials that will meet your unique ultrasonic (UT) requirements.

V-2

Specifications

- ASTM E164

- Made in USA

- 1018 Steel

- Al, S/S. POA

Calibration Function

- Straight beam (distance)

- Angle beam (index point, sound path angle 30º-70º)

Test Residue Removal – Pyro-Clean®

The new ATS Pyro-Clean® is a must have for any testing lab. Applied Test Systems designed the PYRO-CLEAN to burn off test residue from lab equipment, its improved and now incorporates state of the art touch screen technology, automatic operation and a clean, matte-black design.

Lab technicians no longer need to rely on scraping,

wire brushing, or hand heating to clean equipment.

Operators can simply place everything in their Pyro-Clean, press start and allow the Pyro-Clean to do the work. This not only reduces mess, but saves time and creates a safer, more efficient lab environment with COVID-19.

Pressure Aging Vessel – PAV4®

The ATS Pressure Aging Vessel (PAV4) simulates in-service oxidative aging of asphalt binder through exposure to elevated temperatures in a pressurized environment. Our PAV4 has a user-friendly touch screen and new & software version, providing the highest level of efficiency and reliability during testing.

Introducing the new, CE certified PAV4. The PAV4® is everything you need, with improved specifications to make it better than ever. Upgraded heating elements allow for a faster recovery time of 30 minutes or less. Updated, enhanced software provides the highest level of efficiency and reliability. The voltage range has changed as well. With a 208-240 capacity, this range of power allows the PAV4 to be operated in more labs than ever before

25% OFF

Miniature Angle Beam Blocks

‘1018 Steel’ NOS, USA Made

Industry: Steel manufacturing

Material/Part type: Steel

Measuring parameter: Magnetic dipole moment

Industry norm: IEC 60404-14

FOERSTER device: KOERZIMAT 1.097 MS

In steel manufacturing, the final products (whether raw materials or semi-fi nished parts) often contain a number of material phases, e.g. austenite, ferrite and martensite. These phases can be analysed using electron/optical microscopy or X-ray diffraction methods. But, unlike these methods, the saturation polarization (SP) approach not only requires little to no specimen preparation but also delivers very quick and precise analyses. This magnetic method is best suited when the material contains only a few phases.

In stainless steels, for example, the martensite, ferrite and austenite phases are all present in various proportions (e.g. duplex or ferritic stainless steels). Each phase is catalysed by a certain alloying element: For example, Cr is a ferrite phase creator, whereas Ni is an austenite stabilizer. The magnetic phases have mechanical properties (hardness, porosity, brittleness) that can be undesirable for some applications, such as when the steel is to be used for making tools or highly stressed thin metal bands; in this case, it is important to know the percentage of martensite and other magnetic

phases. Here SP provides fast and precise monitoring of the magnetic phase, both during manufacturing (after thermal treatments and cold working) and at incoming goods inspection.

In terms of their magnetic properties, martensite, bainite and ferrite have a clear ferromagnetic nature, whereas the austenite phase is “non-magnetic” (paramagnetic). This physical difference plays a key role in the SP approach, since the measurement of SP makes it possible to determine the percentage of magnetic phases in the tested material.

FOERSTER’s KOERZIMAT 1.097 MS measuring system enables the determination of magnetic phases based on the SP method. The underlying method of the device can be generally described by the following formula:

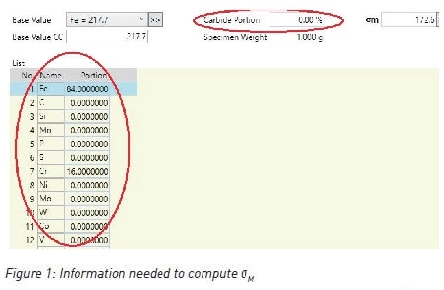

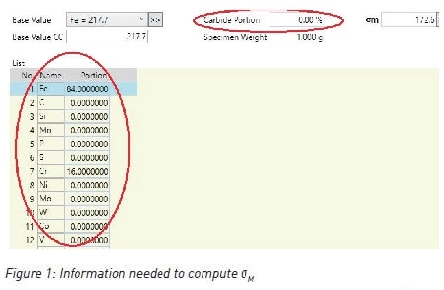

where MP is a magnetic phase to be determined (in %), is a weight-specific saturation polarization measured using the KOERZIMAT device and is a theoretical value of the weight-specific saturation polarization associated with only the magnetic phases of the steel being tested. To compute , the KOERZIMAT MP software module requires the following information (Fig. 1):

■ Mass portion (in %) of the various alloying components, available during production

■ Percentage of carbide, from information collected through metallographic analysis typically done once before production for each alloy.

The advantage of integral measurement with this system is that it requires no specimen preparation, and the specimen’s geometry exerts no influence on the result.

For the determination and analysis of the magnetic and austenitic phases of steels, we recommend the KOERZIMAT 1.097 MS system. For further information or application information please contact us