|

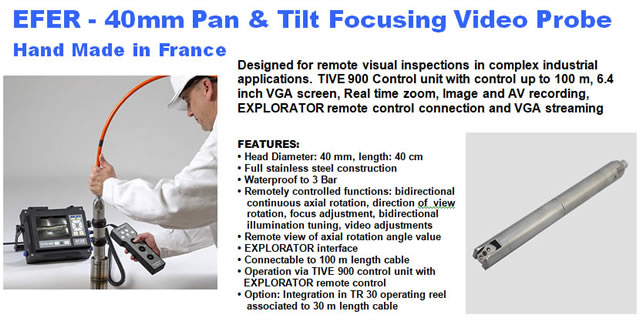

In This Issue: 1. DEUTROFLUX – Universal Magnetic Particle Test Benches 2. News – From the Sales Desk – Foerster- KOERZIMAT® 1.097 Efer-TIVE 900 – 40mm Pan & Tilt, Focus Video 3. Special – Parker A210S Super-Lift Yoke 4. Application – Fischerscope XRF Solution analysis

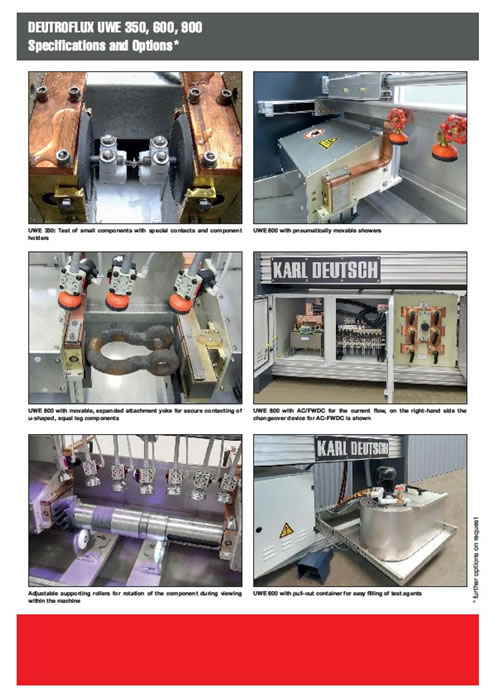

Universal Stationary Magnetic Particle Test Benches Aircraft Engine Parts, Small Components or Railway Rolling Stock, whatever you intend testing with Florescent Magnetic Particle, Karl Deutsch of Germany have a test bench to do it with. Karl Deutsch offers their lifetime quality and tested Deutroflux range to cover every component test.

Two phase-shifted Alternating fields generate a rotating magnetic field; thus cracks of any direction are indicated in a single process. Operating errors are impossible by automatic cycle sequence (clamping, spraying, magnetizing, re-magnetizing, and demagnetizing). Electronics and pneumatics modules from world-wide well-known manufacturers guarantee highest operational reliability and service, even after many years. Flanged switch cabinet is easily accessible for operation and service. Each spraying shower individually switched on and off having short spraying times. Double versatility: As a compact unit it can easily be altered to other applications. Fluxa agent containers with angled bottoms without corners in the pump range and a circulation pump lead to no sedimentation in the container. Braided wire contacts are rotatable and vertically adjustable for long life and low contact losses. Adapted inspection cabin and LED illumination our speciality. Optimum performance with Low space requirements are stand out features for Karl Deutsch.

Like more Information – 02 8850 3755

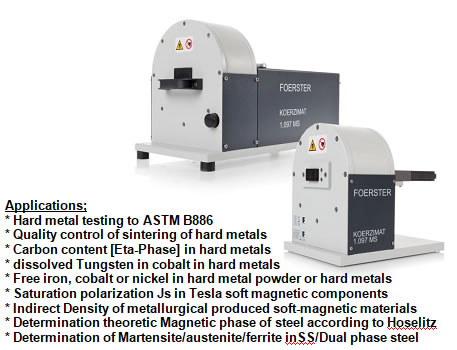

With the KOERZIMAT 1.097 MS FOERSTER offers a measuring system for the precise, automatic and economic measurement of the weight-specific saturation polarization σs and the volume-specific saturation polarization Js. As the measurement is geometry-independent it enables especially for testing of specimen with complex shapes.

Like more Information – 02 8850 3755The Most Powerful Probe Available, Super-lift for Critical asset Testing even through Galvanizing, from Parker the inventor of the Articulated Yoke. Comes with Parker’s Famous user damage parts Warranty

Like more information– 02 8850 3755

Typical electroplating baths are:

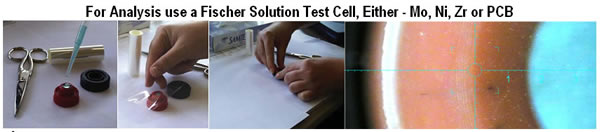

Instruments: Fischerscope proportional counter instruments like the XDLM are widely used for analysis of electroplating solutions in the g/l range. Fischerscope Silicon PIN & Drift instruments are better for low concentration due to better energy resolution & signal to noise ratio. Detection limits and other limitations: Rule of thumb for quantification for electroplating baths, the Fischerscope Proportional Tube instruments is around 1 g/l and for around 0,1 g/l the Fischerscope Silicon PIN and Silicon Drift Detector instruments are required . Detection limits must be determined individually. If electroplating baths contain large amounts of additives, this will also have a significant influence on the detection limits. Sample preparation:

Old solutions like these must be homogenized prior to the measurements by stirring and or heating up to 60-70 °C.

Reference material: Often it is not a requirement to determine the absolute value of an electroplating bath, but event with the WinFTM standard free Fundamental Parameter method good results are achieved in monitoring of the bath change made easy. If very precise measurements are required it is recommended to use the respective bath for calibration. The concentration of the bath is determined with other chemical methods, like AAS, ICP, titration. To achieve optimum results stick to the same cell for every test. The advantage of using the Fischerscope XRF it is that it is Fast and Repeatable. Testing can even be carried out during night shift production, when highly trained lab people may not be on site for other complex test methods. For further application information on Fischerscope X-Ray, please Contact KK&S Instruments; www.kks.com.au Have any questions or like further details?; Ph 02 88503755 or Email

|

The Best in Quality Service and Products for Non destructive testing