|

In This Issue: 1. Cover Story – Two NEW! Model Tracerco PED’s 2. Special – FREE Delivery of Ardrox 3. News – New! SIGMASCOPE from Helmut Fischer – New! MAGNATEST D 3.623 from Foerster 4. Application – Measurement of the sealing quality of Anodizing

New Personal Electronic Dosimeter (PED) Tracerco will soon be launching a new extended family of PEDs. The PED family has been designed to be easy to use and understand. Everything on the PED’s has been designed with the user in mind, from the simple display, to the one button operation, and easy to use software. The products available in this Personal range are;

The original T404 PED. “Intrinsically safe”, robust and easy to use.

The PED Blue, has a 10% weight saving and can be charged with USB connection. With DoseVision™ software, the PED Blue is aimed at first responders, medical and life sciences, nuclear, industrial and in NDT.

The PED+, a personal dosimeter & survey meter in one. Off-body mode measures activity through a live trend graph and logged data can be reviewed using DoseVision. The PED+ has alarm and pop-up message system, which communicates procedures, for example, exclusion zones. PED + also supported by mobile Bluetooth for an overview of up to 7 x PED+ devices (15m radius). Data logged by location via Bluetooth and GPS FREE Delivery ANYWHERE in NSW

Minimum Order 1 Carton Other States P.O.A. Offer Ends April 30th Helmut Fischer Launch their NEW SIGMASCOPE® GOLD C, for testing coins and thin ingots (up to approx. 100 g)

This new model compliments the existing range including; SIGMASCOPE GOLD B for testing bullion, 1 oz to 1 kg For thicker gold bars up to 1 kg. As measurements are taken from both sides, the bars can be analysed in their full depth so the authenticity of the alloy or fine gold can be verified. Even concealed inclusions of ignoble materials with matching density such as Tungsten can be detected clearly with SIGMASCOPE GOLD. Foerster – Magnetische Pruefanlagen GmbH, launch their new Magnatest D 3.623, for manual or automatic magnetic-inductive non-destructive material testing

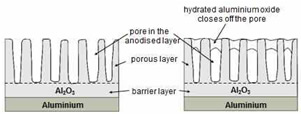

Weather resistance of sealed anodised Coatings

Pure aluminium is highly susceptible to corrosion. However, in contrast to iron, it naturally forms a corrosion-inhibiting layer on its surface when it comes into contact with oxygen, which preserves it very well under normal environmental conditions: When this protective oxide layer is scratched away it is quickly replenished upon renewed exposure to oxygen. Nonetheless, for many applications, especially out-ofdoors, this natural protection does not suffice because even the smallest entrapment of heavy metals can prevent the formation of a seamless oxide layer, allowing corrosion to get in and cause damage.

Although the ultimate quality of the sealing depends on a variety of factors including the condition of the oxide layer, the hydration time, the sealing bath temperature, the pH value of the solution, etc., it can be examined simply and non-destructively by measuring the electrical admittance (Y). Using FISCHER’s handheld ANOTEST® YMP30-S instrument, the coating’s admittance can be determined in situ according to standards such as DIN EN ISO12373-5 and ASTM B 457-67. An electronic reference is also available for cross-verification of the instrument. With the ANOTEST® YMP30-S, the sealing of anodised aluminium can be tested by measuring its electrical admittance. This makes it possible to determine the corrosion resistance of façades and other aluminium components exposed to weathering influences. Have any questions or like further details?; Ph 02 88503755 or Email |

The Best in Quality Service and Products for Non destructive testing

Tracerco PED – ‘IS’

Tracerco PED – ‘IS’

The SIGMASCOPE GOLD C offers 4 unique measurement ranges, technically optimised for authenticity testing of a huge variety of different precious coins and thin ingots.

The SIGMASCOPE GOLD C offers 4 unique measurement ranges, technically optimised for authenticity testing of a huge variety of different precious coins and thin ingots.

Aluminium is often used for architecturally pleasing building façades and other structures exposed to weathering influences. Lightweight and fairly easy to work, it is also durable and requires little to no maintenance over the long term when effectively protected by an anodised coating. But to ensure the reliability of the corrosion protection, the sealing of the coating must be verified.

Aluminium is often used for architecturally pleasing building façades and other structures exposed to weathering influences. Lightweight and fairly easy to work, it is also durable and requires little to no maintenance over the long term when effectively protected by an anodised coating. But to ensure the reliability of the corrosion protection, the sealing of the coating must be verified.